- #Siemens step 7 license key

- #Siemens step 7 windows 10

- #Siemens step 7 code

- #Siemens step 7 trial

- #Siemens step 7 series

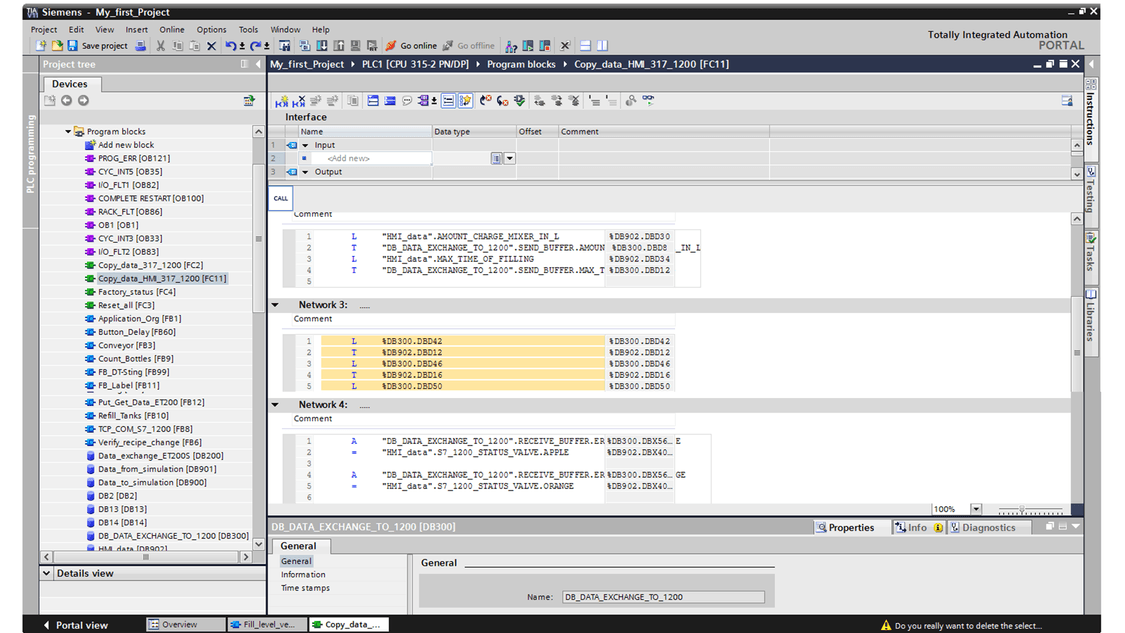

Thanks to its integration in the engineering framework of TIA Portal, SIMATIC STEP 7 offers advantages such as direct online diagnosis, easy adding of technology objects or the library concept which is both time-saving and efficient when working with and reusing objects.

#Siemens step 7 windows 10

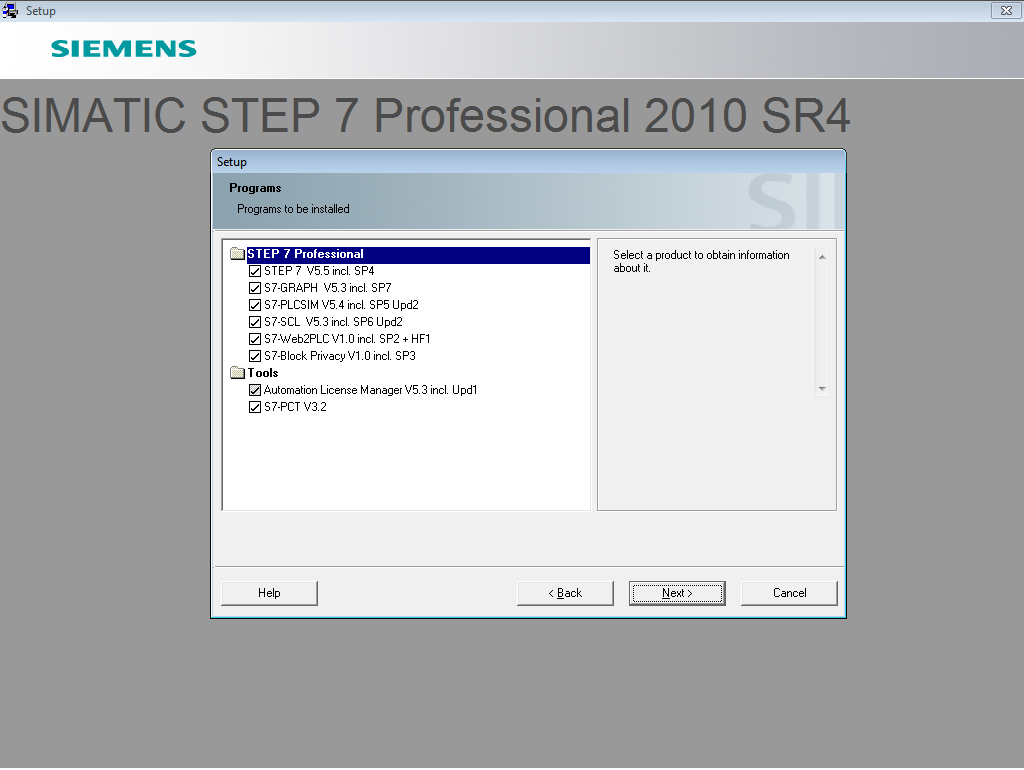

on DVD Class A 6 languages: de,en,fr,es,it,zh Executable in Windows 7 (64-bit), Windows 10 (64-bit), Windows Server 2012R2 (64-bit), Windows Server 2016/2019 (64) for configuration of SIMATIC S7-1200/1500, SIMATIC S7-300/400/WinAC, SIMATIC Basic Panels ******************************* Content: Set (4x DVD) With SIMATIC STEP 7 (TIA Portal), the user configures, programs, tests and diagnoses Basic, Advanced and Distributed Controllers of all generations, whether PLC or PC-based, including software controllers.

#Siemens step 7 trial

V16 Trial for 21 days Engineering Software in TIA Portal SW and docu. In order to protect plants, systems, machines and networks against cyber threats, it is. STEP 7 in TIA Portal helps you to solve engineering tasks intuitively and efficiently. STEP 7 V5.6 SP1 Programming Software for SIMATIC S7 / C7 Security Information: Siemens provides products and solutions with industrial security functions that support the secure operation of plants, systems, machines and networks.

#Siemens step 7 license key

V16 Floating License download Engineering Software in TIA Portal software, documentation and License key for download Class A 6 languages: de,en,fr,es,it,zh executable in Windows 7 (64-bit), Windows 10 (64-bit), Windows Server 2012R2/2016 for configuration of SIMATIC S7-1200/1500, SIMATIC S7-300/400/WinAC, SIMATIC Basic Panels ******************************* E-mail address required for delivery With SIMATIC STEP 7 (TIA Portal), the user configures, programs, tests and diagnoses Basic, Advanced and Distributed Controllers of all generations, whether PLC or PC-based, including software controllers. I'm guessing I'll have to track down where DB301 is called and work backwards again.SIMATIC STEP 7 Prof. In my case the outputs are Q263.3-6, but all I see in the program is DB301. There has to be a way find out which base-slot-output as specified in the hardware config. I had to cross reference the prints with the program to find the actual outputs. Can anybody give me a laymen's term explaination of DBs and how they're used in this instance. What I still don't have my head wrapped around is DB301(Base 18 Inputs/Outputs) somewhere this DB has to be tied to those I/O cards but I not sure how.

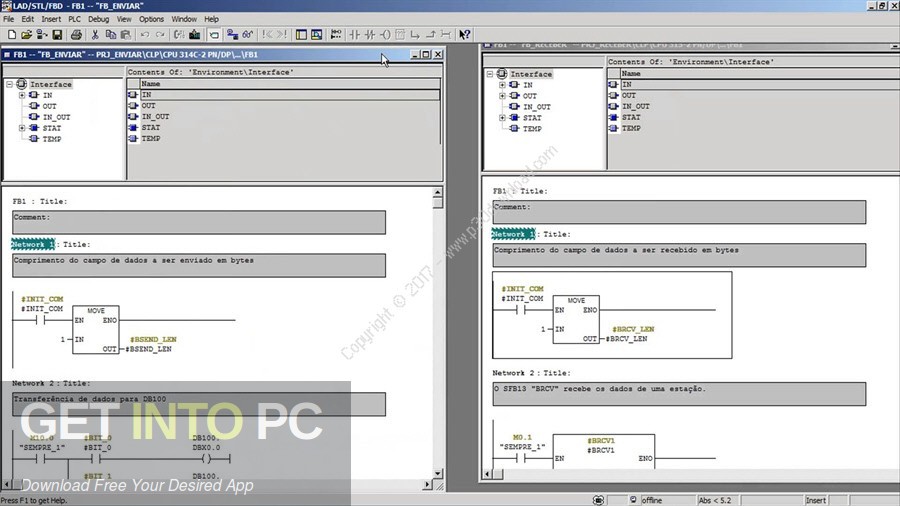

#Siemens step 7 code

I know enough to write the code for another press, although it's twice the size with 2 Unit groups, the logic/idea is the same. Data" took me the rest of the way, leading me to FC35 where the LAD logic written. It took some digging but I found that DB201 in the System PLC Blocks, is where all the data is read from DB11 in UG1. Well, I was able trace the I/O from UG1 to the System PLC, out to base 18.

#Siemens step 7 series

This system uses the 400 series for the Unit Group 1 and System PLCs. I even tried programming a coil with current output that's being used, and did a Go To.

I know you can use the Go To, but it shows no results. Also, is there a way to back trace from a known input/output address to find where it's used when it's not addressed in your typical coil function in LAD. Displaying "Reference Data and the "Go To" just aren't working for me, but I could be using them wrong. I would like to be able to efficiently find a starting point on really anything, and be able to trace it all the way back. Something has to be reading the UG1 data that I then can use to fire the spare outputs required.Īny advice on a methodical approach to troubleshooting Step 7 programs would be appreciated. The screen shots are from a Press where this is working, so somewhere it has to be tied to Q263.? on rack 17. This leads me to believe that I can't directly address rack 17 on the Sys PLC profibus network from UG1, rather it has to be addressed from the Sys Plc. In FB34, the Ink Solenoids (Upper and Lower) are tied to DB11 which is sent to the Sys PLC. The most common form of addressing used in the Siemens S7 PLCs is direct and symbolic. Check out their website for hands-on and online training classes. This is a really nice explanation of a difficult but important subject. The pics I uploaded will explain what I'm talking about. The following is provided by Automation Training from their excellent Siemens Step 7 training manual. How do you find an input or output or where is it called from/written to, in a Step 7 program The program is 80% STL and from what I can see there is almost no direct inputs or outputs addressed even in the FC that are in LAD. This interlocking has been done on another and I'm trying to use it as a guide, as I'm new to FBD programming. I've been tasked to add a simple interlocking function on a piece of press equipment.

0 kommentar(er)

0 kommentar(er)